thermal conductive silicone potting compound with UL certification

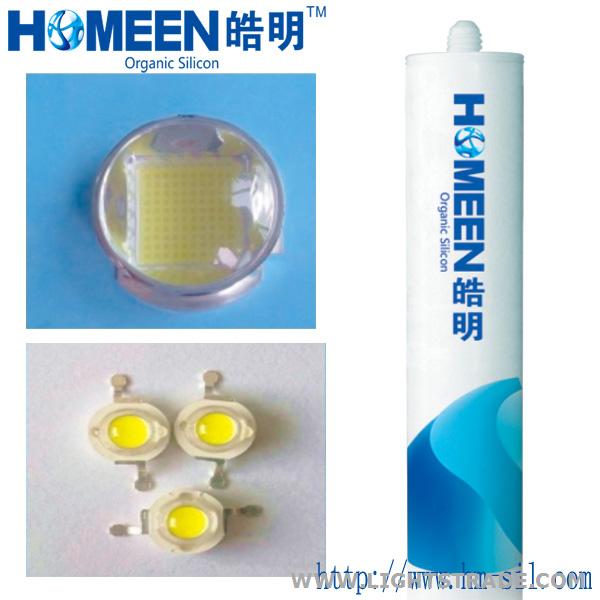

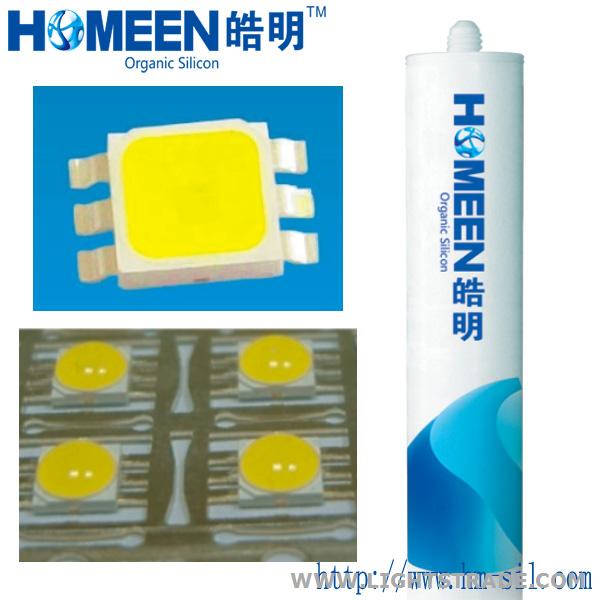

electronic silicone sealant for LED lights

MOQ :2000 piece

Lead Time :3 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Western Union, Money Gram, Credit Card, Paypal

Product details

Supply Ability

- Supply Ability:60000 piecesWarranty(Year):1 Year

Packaging & Delivery

- Length:35 cmWidth:35 cm

- Height:18 cm

- Packaging:24 piece

Product Specifications

- Brand name:haoming

Product Description

electronic silicone sealant for LED lights silicone rubber adhesive sealant high temperature rtv silicone

? One component electronic silicone sealant

? Neutral,room temprature cure

? Widly used in LED ,consumer electronics devices ,etc .

? UL,REACH,RoHS certificates

Haoming is a leading chinese manufacturer for onecomponent and two components silicone sealant ,which are widly used in craft,LED,Solar PV ,consumer electronics ,automobile,etc.Our products includesilicone rubber, RTV-2 mold making silicone, RTV liquid silicone rubber,thermalconductive silicone potting compound,electronic silicone conformalcoating,silicone encapsulant,electronic silicone sealant,general purposeneutral silicone sealant,gasket silicone sealant .For more information aboutour silicone sealant ,pls contact Mandy Hong marketing1@hm-sil.com www.homeen-sil.com www.haomingsilicone.com

HM -538 Neutral Sealant

One part room temperatureoxime cured silicone sealant, passed UL,SGS certificate. With excellentresistance to climatic aging and yellowness; high strength, have good adhesionfor aluminum, glass, etc.

electronic silicone sealant for LED lights silicone rubber adhesive sealant high temperature rtv silicone

Applications

Bonding, sealing, andencapsulating photovoltaic module components.

Main parameters

Item | Result | Test Standard |

color | Black, white or grey paste | visual inspection |

Tack-free time (min) | 8~20 | GB/T13477 |

Hardness(HSA) | 42~50 | GB/T531 |

Specific gravity(g/cm3) | 1.40 | GB/T13477 |

Tensile strength(MPa) | ≥2.0 | GB/T528 |

Metal corrosion test | qualified | SH/T0331-1992 |

Working temperature(℃ ) | -50~220 | / |

flame retardant rating | UL94HB | / |

electronic silicone sealant for LED lights silicone rubber adhesive sealant high temperature rtv silicone

How to use

Substratespreparation

A.All surface must be clean and dry, degrease and wash off any contaminates thatcould impair adhesion.

B.Certainplastic may require specific surface treatment to obtain optimum adhesion. Suchas the polypropylene, which should need chemical corrosion or plasmatreatments?

Howto apply

A.Apply a bead of neutral sealant to one of the prepared surface, and thenquickly cover with the other substrate to be bonded.

B.On exposure to moisture, the freshly applied material will “skin over” in about10 to 15 minutes at room temperature and 50% relative humidity. The surface iseasily tooled with a spatula.

Cured time

electronic silicone sealant for LED lights silicone rubber adhesive sealant high temperature rtv silicone

Afterskin formation, cures continue inward from the surface. In 24 hours(at roomtemperature and 50% relative humidity),will cure to a depth of about 3.0mm.Verydeep sections, especially when access to atmosphere moisture is restricted,will take longer time to cure completely. Cure time will also extend when atlower humidity levels.

Usable life and storage

Whenstored at or below 27℃ in the original unopenedcontainer has a usable life of 9 months from the day of manufacture.

Package

Plasticbarrel: 5 gallon (about 18L)

You May Like

- Free Member

- Trade Assurance

Company Location:

You May Like

-

thermal conductive silicone potting compound with UL certification

-

thermal conductive silicone sealant with high thermal conductivity

-

electronic silicone sealant for LED lights

-

conformal coating for circuit board HM-2577

-

conformal coating silicone coating potting circuit boards pcb sealant HM-301T

-

potting adhesive silicone sealant adhesive sealant 1060

-

silicone encapsulant for LED ,LED Encapsulating Materials HM-6101A/B

-

transparent silicone encapsulant transparent electrical potting compound for LED display

-

silicone encapsulant for LED with high refractive index

-

electrical electronic adhesive glue sealant silicone rubber adhesive