thermal conductive silicone potting compound with UL certification

silicone encapsulant for LED with high refractive index

MOQ :2000 piece

Lead Time :3 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Western Union, Money Gram, Credit Card, Paypal

Product details

Supply Ability

- Supply Ability:60000 piecesWarranty(Year):1 Year

Packaging & Delivery

- Length:35 cmWidth:35 cm

- Height:18 cm

- Packaging:24 piece

Product Specifications

- Brand name:haoming

Product Description

silicone encapsulant for led lights encapsulating compound encapsulating compound

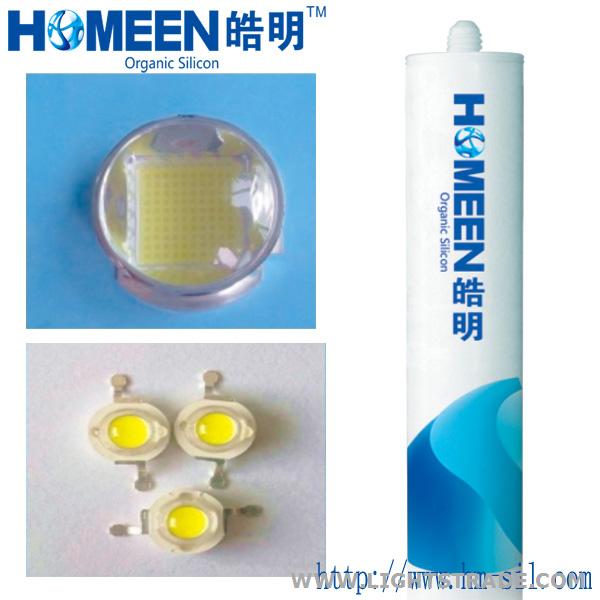

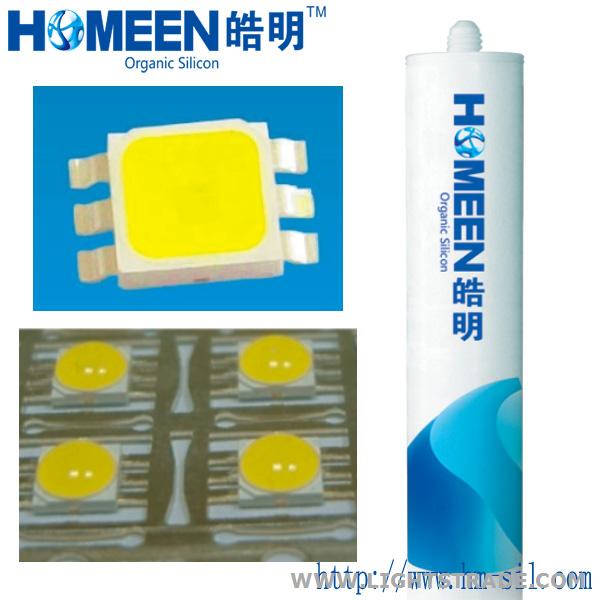

1.High Refractive Index Silicone LED Packaging Material

2.two-part, high refractive index, clear, heat cure silicone encapsulant for LED lighting.

Haoming is a leading chinese manufacturer for onecomponent and two components silicone sealant ,which are widly used in craft,LED,Solar PV ,consumer electronics ,automobile,etc.Our products includesilicone rubber, RTV-2 mold making silicone, RTV liquid silicone rubber,thermalconductive silicone potting compound,electronic silicone conformalcoating,silicone encapsulant,electronic silicone sealant,general purposeneutral silicone sealant,gasket silicone sealant .For more information aboutour silicone sealant ,pls contact Mandy Hong marketing1@hm-sil.com www.homeen-sil.com www.haomingsilicone.com

HM-7101A/B

Directions:

The HM-7101A/Bis formed by two parts potting adhesive, with1.41 refractive index.Normally used as potting adhesive in LED patch, and high and low power LEDmodule encapsulation like 3014、3528、5050、5630 surfacemount devices,thisbinding agent has good adhesive strength for PPA, PCB and metal material.

silicone encapsulant for led lights encapsulating compound encapsulating compound

Parameters:

|

| A | B | |

Before cured | appearance | Colorless Transparent Liquid | misty-white liquid | |

viscosity | 10000cps | 2000cps | ||

Mixed ratio | 1:1 | |||

Mixed viscosity | 5000cps | |||

Curing condition | precuring:80℃/1hour full cured :150℃/2~4hours | |||

After mixed | >5hours | |||

cured | Appearance | Transparent | ||

hardness | 60D | |||

refractive index | 1.535 | |||

Instructionsfor use:

1. Use the A、B parts according to their mass proportion of 1:1 andconduct the production in the dried and dust-free cirsumstance.

2. Before adhesive dispensing please clean the bracket thoroughly to get ridof the material which may hinder curing of adhesiv from the baseplate

3. Stir by Planetarygravity mixer to make it uniform mixing or emove air bubbles from the adhesiveat 45℃temperature with 10mmHg vacuum deegree before using

4. The bracket should be heated at 150℃ for30 minutes for dehumidification before injection adhesive, and dispenseadhesive before the rack absorb moisture again.

silicone encapsulant for led lights encapsulating compound encapsulating compound

5. Heat the bracket in a 80℃ oven for 1hr then take to another 150℃ ovenbake for 2-4 hours it will be full cured.

6. Put the untapped adhesive into the spotless container for later use

Notes:

1. HM-7101A/B is Additiontype siliconeelastome,which should not touch some material alkyne,lead,tin,cadmiu,mercuryand other heavy metal which may cause uncured or partialy cured.The pottingsuface must be cleaned before sealing and filling.

2. Different operation will result in various consequences may lead tobubble,barrier,debonding,crack etc. Please refer to associated personel toavoid above occurrenc.

3. Better the vacuumizer is an open system and never use forepoxy resin.The best way is to establish a dedicated organic silicon productionline.

silicone encapsulant for led lights encapsulating compound encapsulating compound

4. Please use appropriate container and stirring rod for mixing. And don’t wearsilicon glove to get touch the silicon.

5. Because it is not easy to get rid of the bubbles from the organic siliconduring operation, please heat up starting from room temperature while removingthe buttbles.

6. In case the cememtation is not good generally it is owing to not full vulcanizationcan not adhere to the object, you can increase the temperature or heat itlonger to improve the cememtation.

7. Due to the condistion and method is out of our control, this file can notbe used to replace test,in case there is any query for the material whetherhinder curing,just conduct a small compatibility test to ascertain itsappropriateness for special application or consult our company technical staff/

Storage and transportation:

1. Keep in dark and dried place in room temp.

2. Expiration date 6 months. If all technical tests remianok after expiration date it can be used normally as well.

3. This product can be shipped asnon-dangerous chemicals

4. A,B parts should be sealed for storage,don’tmake any leakage during transporation.

packaging:

A part:0.5kg/bucket;1kg/bucket

B part:0.5kg/bucket;1kg/bucket

You May Like

- Free Member

- Trade Assurance

Company Location:

You May Like

-

thermal conductive silicone potting compound with UL certification

-

thermal conductive silicone sealant with high thermal conductivity

-

electronic silicone sealant for LED lights

-

conformal coating for circuit board HM-2577

-

conformal coating silicone coating potting circuit boards pcb sealant HM-301T

-

potting adhesive silicone sealant adhesive sealant 1060

-

silicone encapsulant for LED ,LED Encapsulating Materials HM-6101A/B

-

transparent silicone encapsulant transparent electrical potting compound for LED display

-

silicone encapsulant for LED with high refractive index

-

electrical electronic adhesive glue sealant silicone rubber adhesive